30 control desks for the GPA automotive recycling plant

01.Brief

GPA, a leader in automotive dismantling, processes 1.5 million vehicles each year in France. To modernize its production line, Johan Renaud, the company's director, requested the creation of 30 control desks. These desks must integrate the operators' work interfaces and machine controls while enhancing the plant's image.

02.User needs analysis

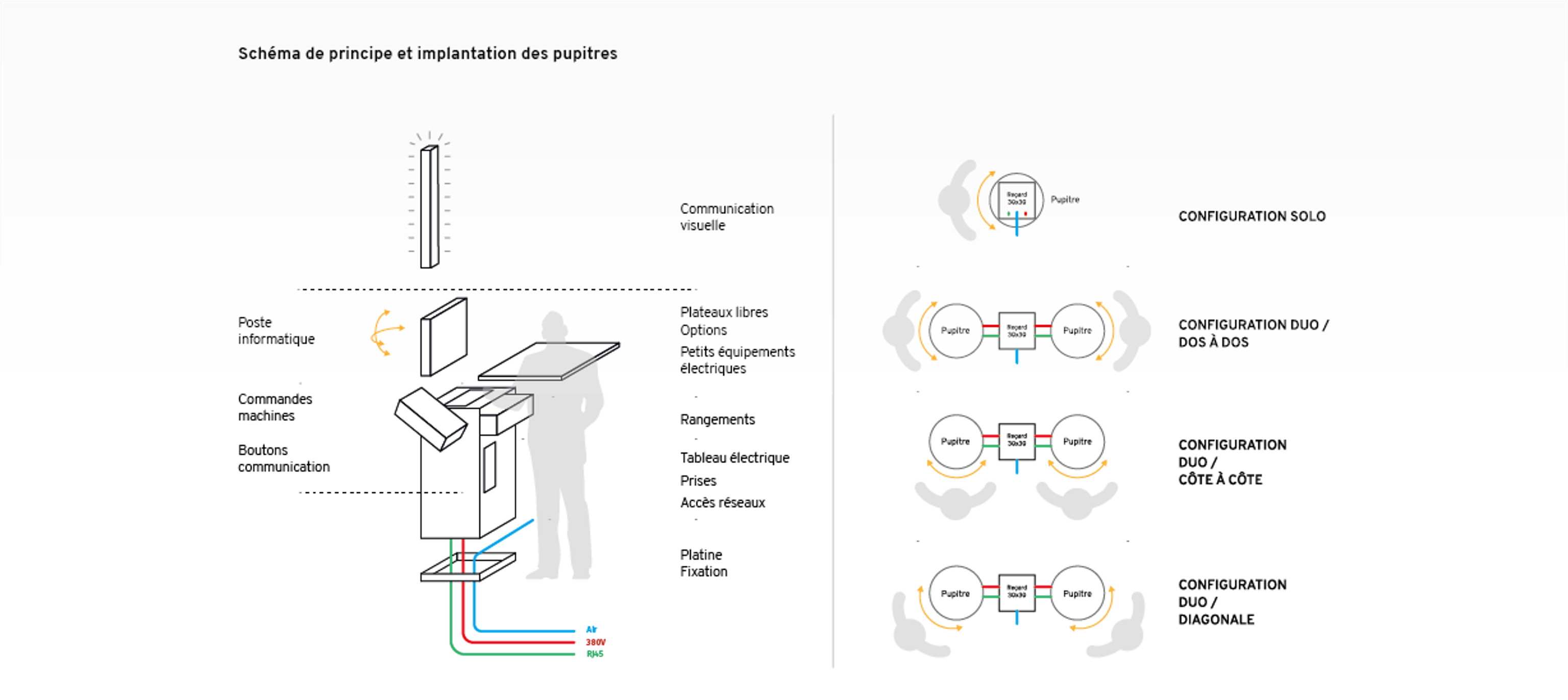

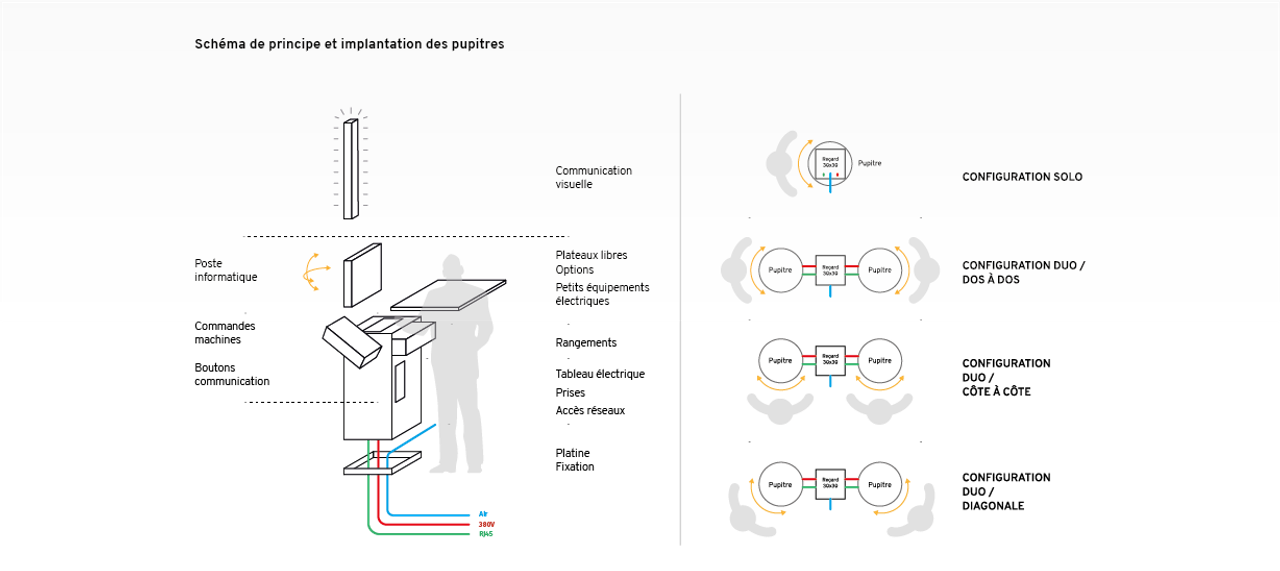

An immersion at the production site helped understand the users' needs. Three key functions were identified:

- Centralization of all equipment at the workstation.

- Facilitation of communication among operators.

- A marker of the company's identity for external communication.The desk must integrate IT tools, communication tools, and machine-specific controls.

" The products system allows for economies of scale "

03.Product design

Initial concepts were developed with a simple architecture. The use of painted steel sheet was chosen for its robustness and ease of fabrication. A systemic approach allowed for the creation of variants tailored to each workstation while optimizing production costs.

04.Mechanical Design and Technical Integration

In collaboration with 8Fablab, engineers designed an active desk equipped with sockets for connecting equipment. A three-button communication system was also integrated to facilitate assistance among operators.

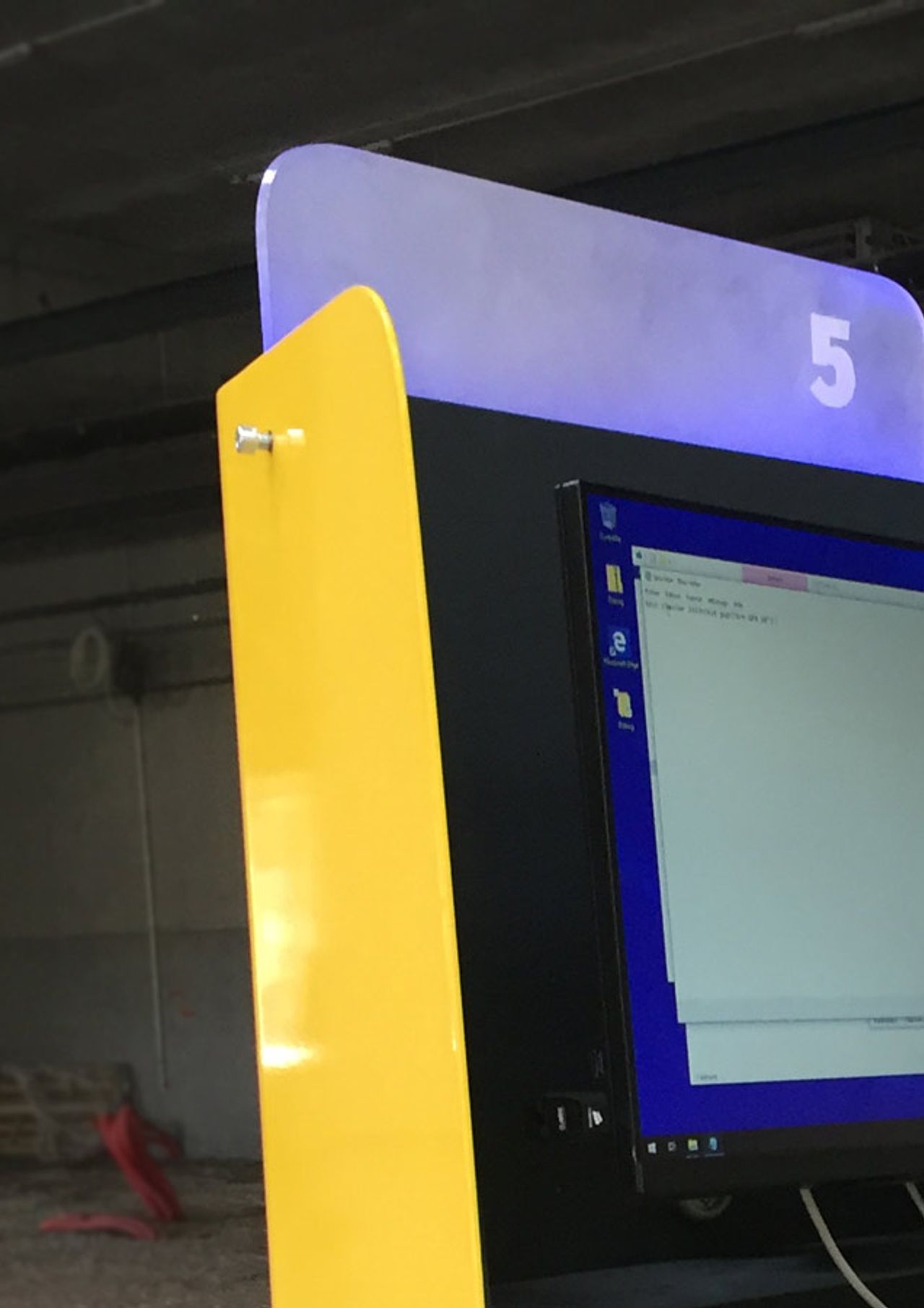

05.Prototyping

The prototype, created with Tolerie Metal Indus in Bourg-de-Péage, allowed for the final technical adjustments before mass production.

06.Industrialization

The project was successfully completed in five months, resulting in desks that reflect GPA's identity. After installation, the teams fully embraced the desks, even customizing them to hold tools.

" A product designed and manufactured with care 50km away "