Collaborating from strategy to industrialized product

01.Brief

YellowScan is a dynamic SME based in Montpellier. It develops LIDAR systems for drones. These devices allow for the scanning and modeling of environments in 3D. Their precision reaches 2.5 cm at a height of 100 m, even through vegetation. Applications include measuring volumes in quarries and exploring archaeological sites.

“Just press the yellow button”

02.Strategic Design

Immersion and Support

We conducted an immersion phase to understand the products and customer interactions. This helped establish a foundation of trust. We analyzed past and current projects, which allowed us to identify successes and areas for improvement. A competitive analysis was also conducted to guide our strategic action plan.

- Highlight the user experience.

- Define values and build a coherent brand identity.

- Identify and prioritize areas for improvement.

- Integrate industrial design into development projects.

- Organize workshops and focus groups.

- Choose a distinctive color for YellowScan.

03.Implementation ‑ design as a service

We integrated design into the company’s processes. Some existing collaborations were revised. New hires were made, including a graphic designer. This strengthened the visual identity and improved YellowScan's presence on social media.

We adopted an agile collaboration model. This allows for increased availability to advance projects. We also provided expert advice to validate ongoing projects.

04.Product Design

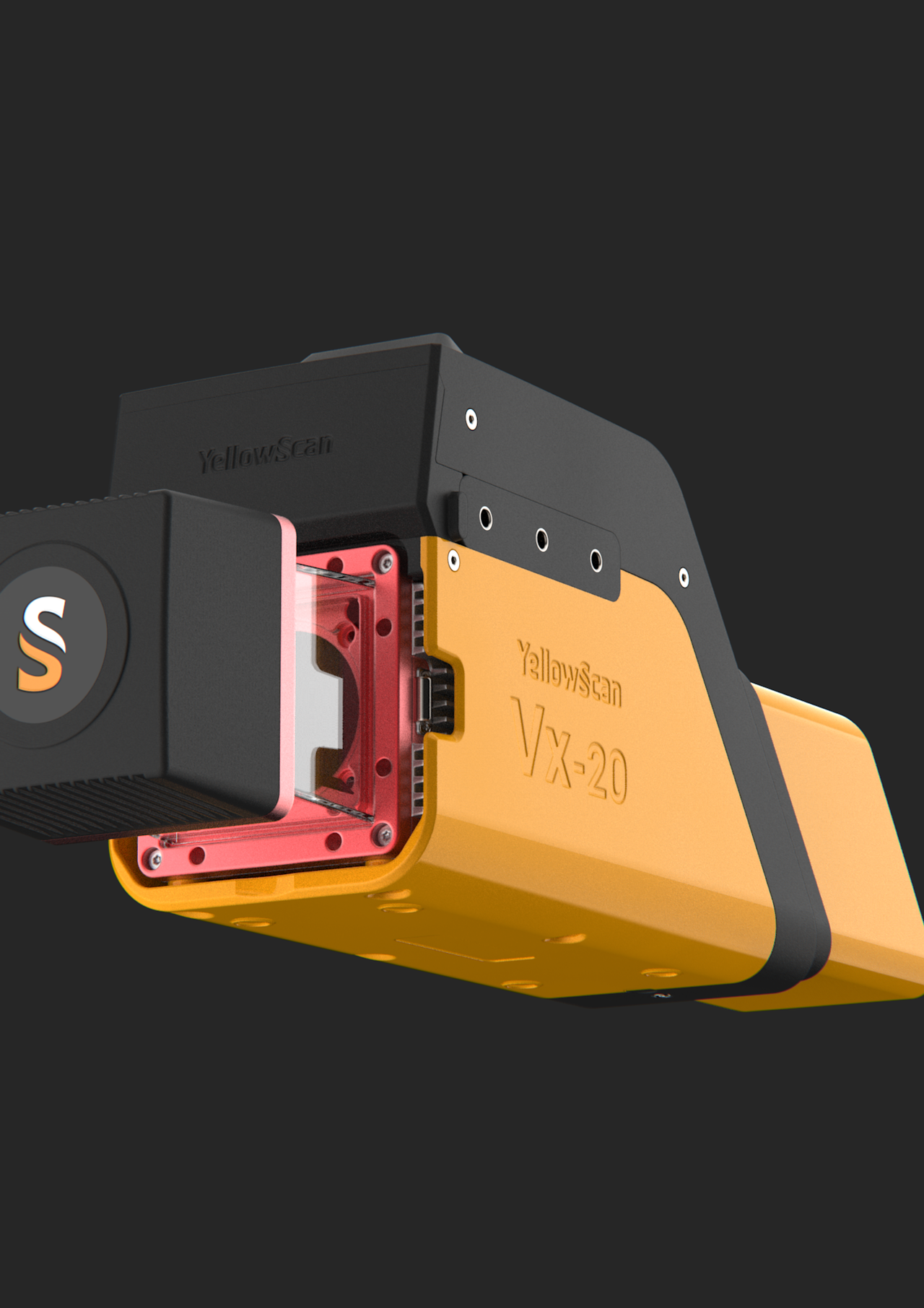

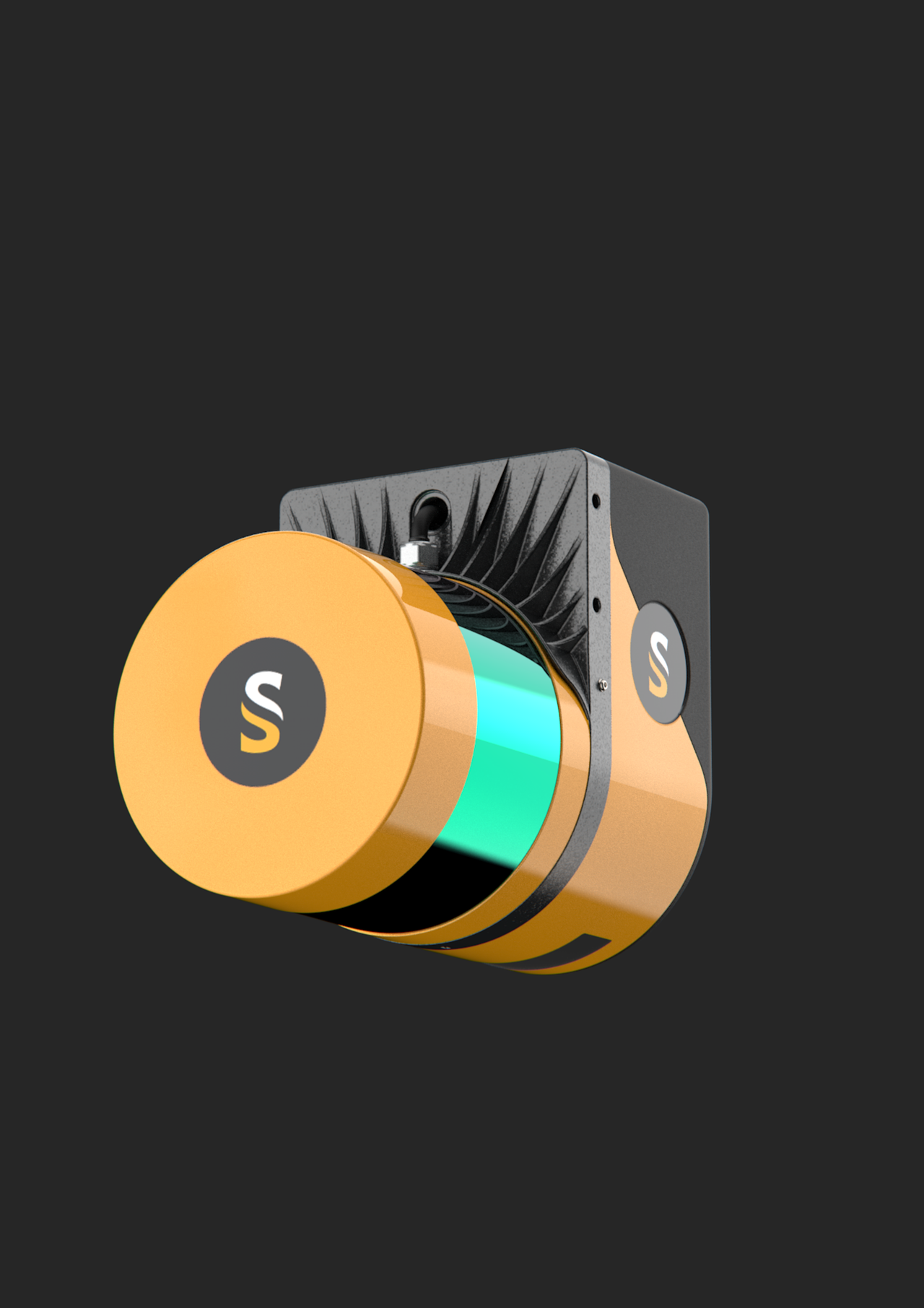

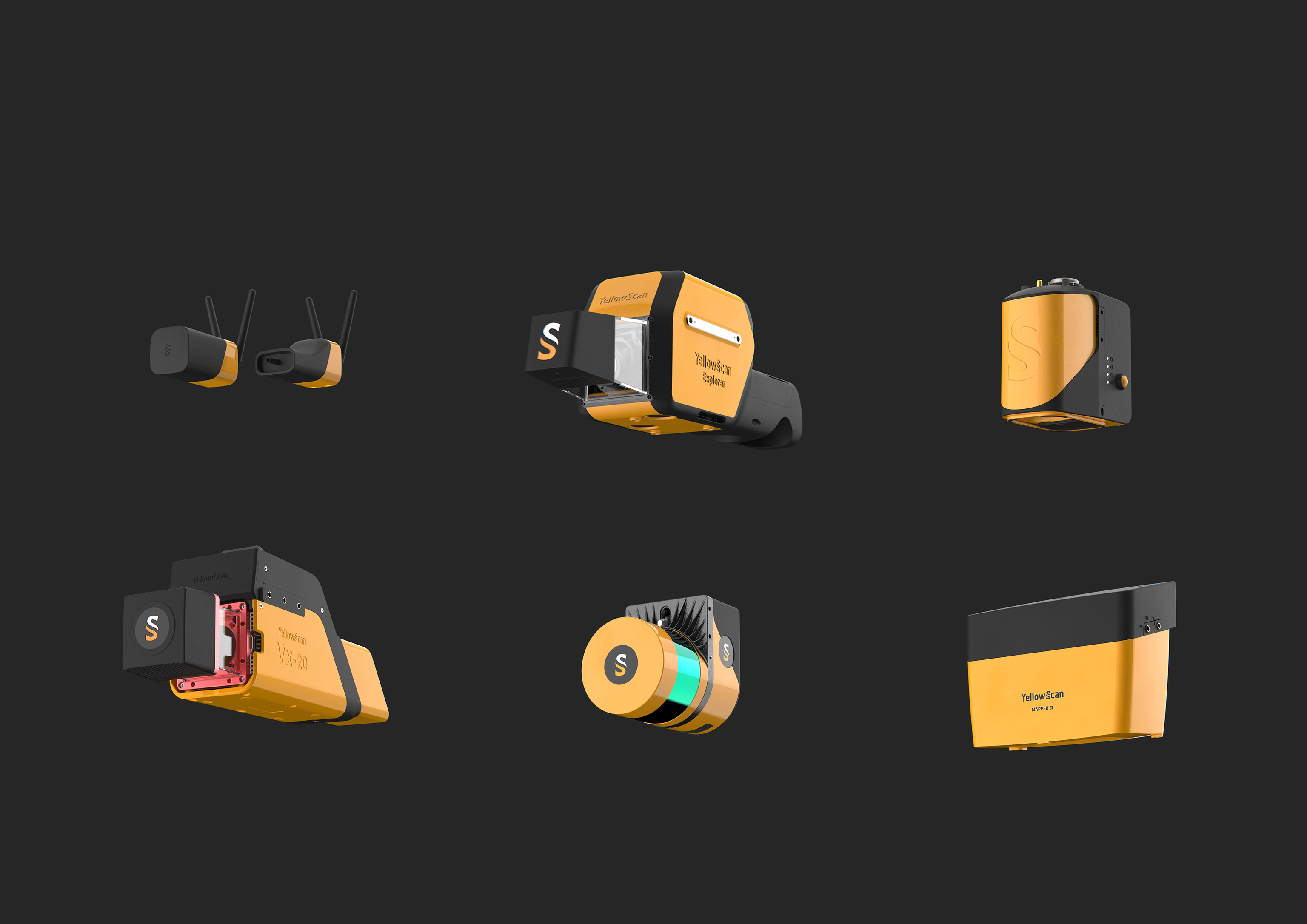

We redefined the product codes. The MODEM served as a foundation for collaboration. Once the formal language was established, we redesigned the historical MAPPER and the premium VX model. These graphic choices reinforce the company’s values.

05.Mechanical Design and Prototyping

We developed simple product architectures that meet strict technical requirements. We recommended machining aluminum parts to ensure rigidity and flatness. Prototypes were created to validate hypotheses and refine specifications.

06.Industrialization

Prototype testing must be complemented by industrial recommendations. Repeated use in the field reveals areas for improvement. The chosen industrial processes, such as additive manufacturing and machining, allow for rapid iteration. These processes facilitate commercialization and the integration of customer feedback for frequent updates.

Results

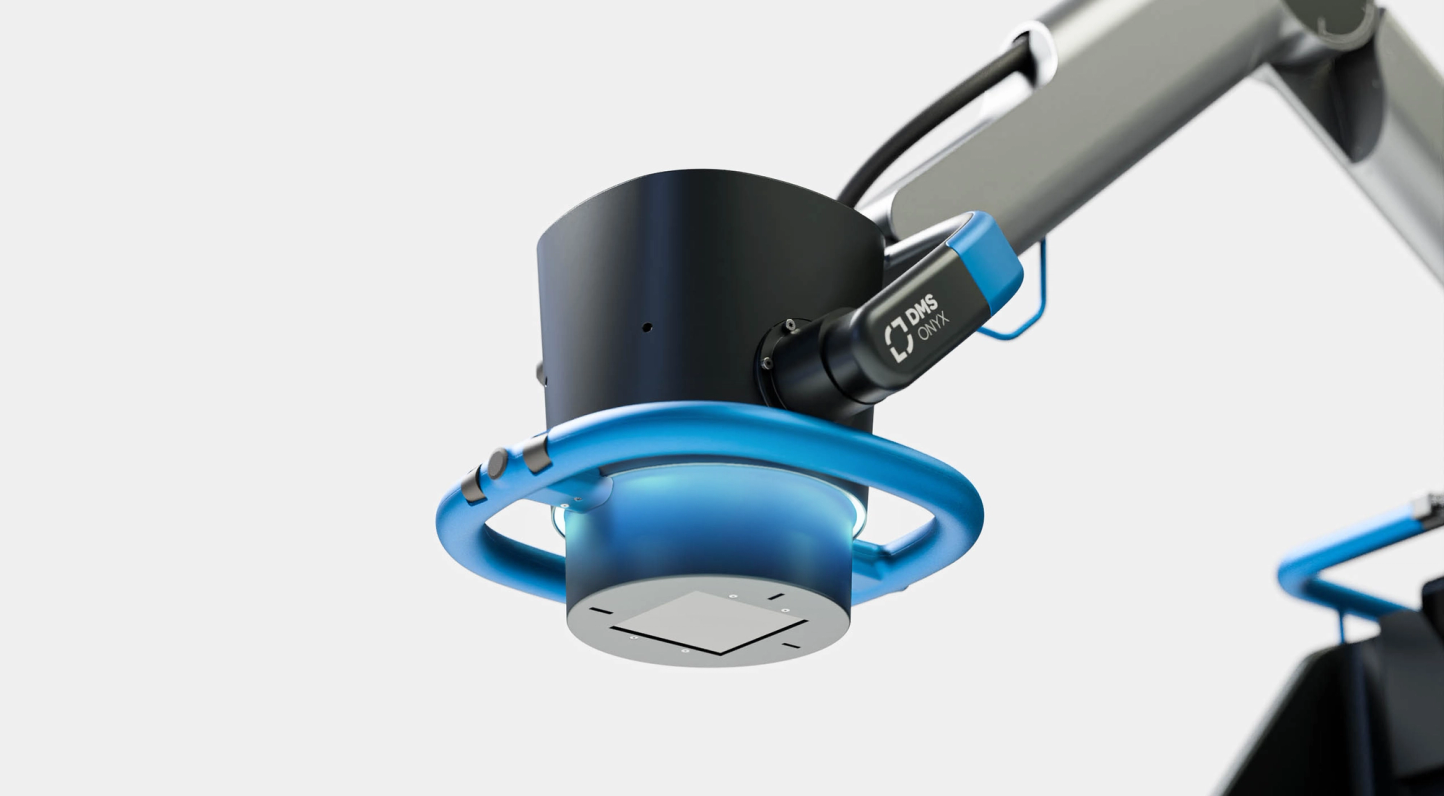

Circularity

A 100% dismountable product design that anticipates the repair and reuse of key components at the end of their life.

Simplicity

A very simple user experience that makes cutting-edge technology accessible to all.