A product system for industrial augmented reality product design

01.Brief

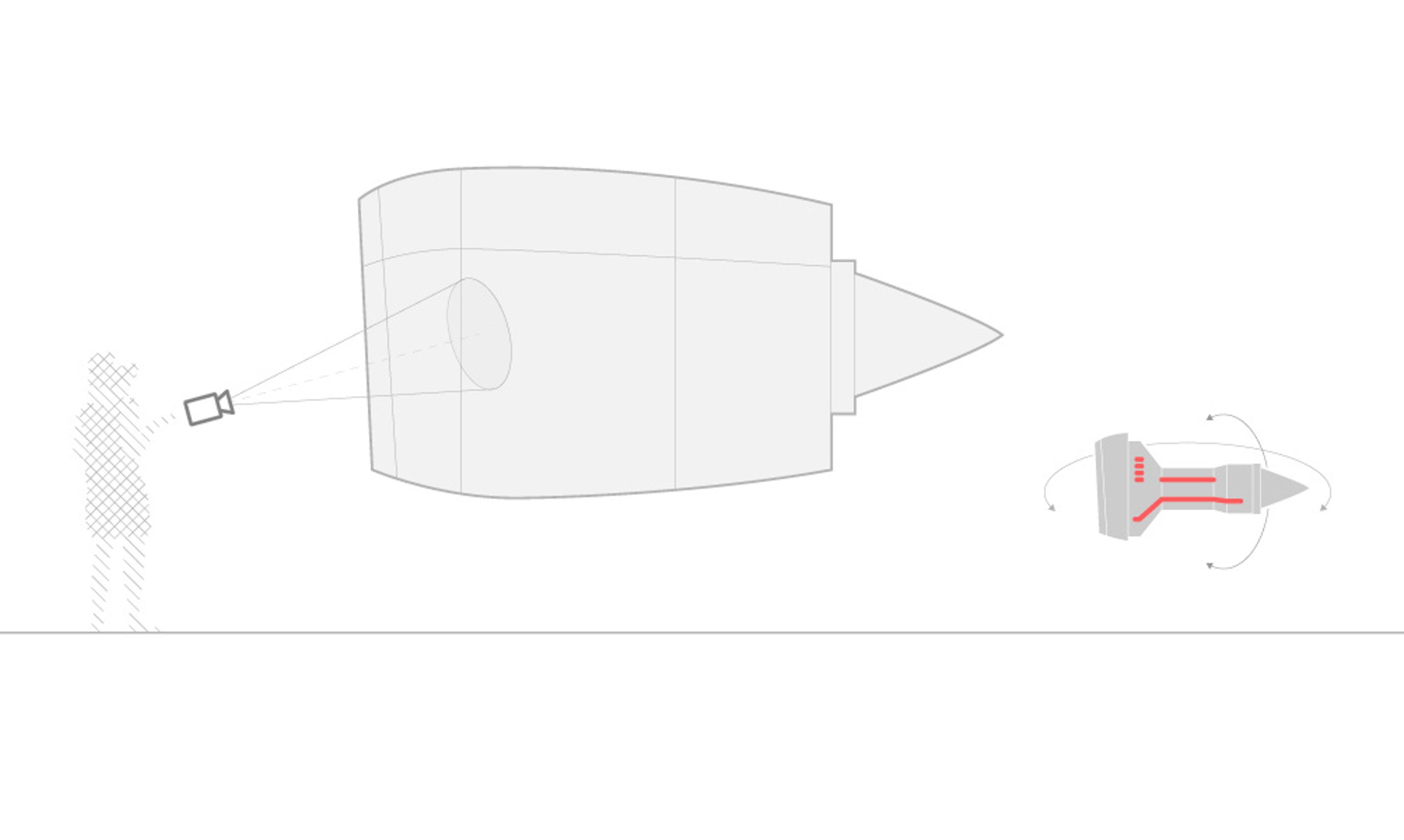

DIOTA supports industrial companies in optimizing processes through digital technologies (augmented reality, 3D scanning, digital twins, AI, etc.). We assisted them in improving WAND : a precision camera that enables image capture on assembly lines for complex products, particularly in the aerospace sector. The WAND camera is designed as an extension of the augmented reality software.With this new version of WAND, the user can film hard-to-reach constrained spaces, benefit from an ergonomic workstation, and obtain perfect images.

" Our product should be essential. "

02.Develop a product system

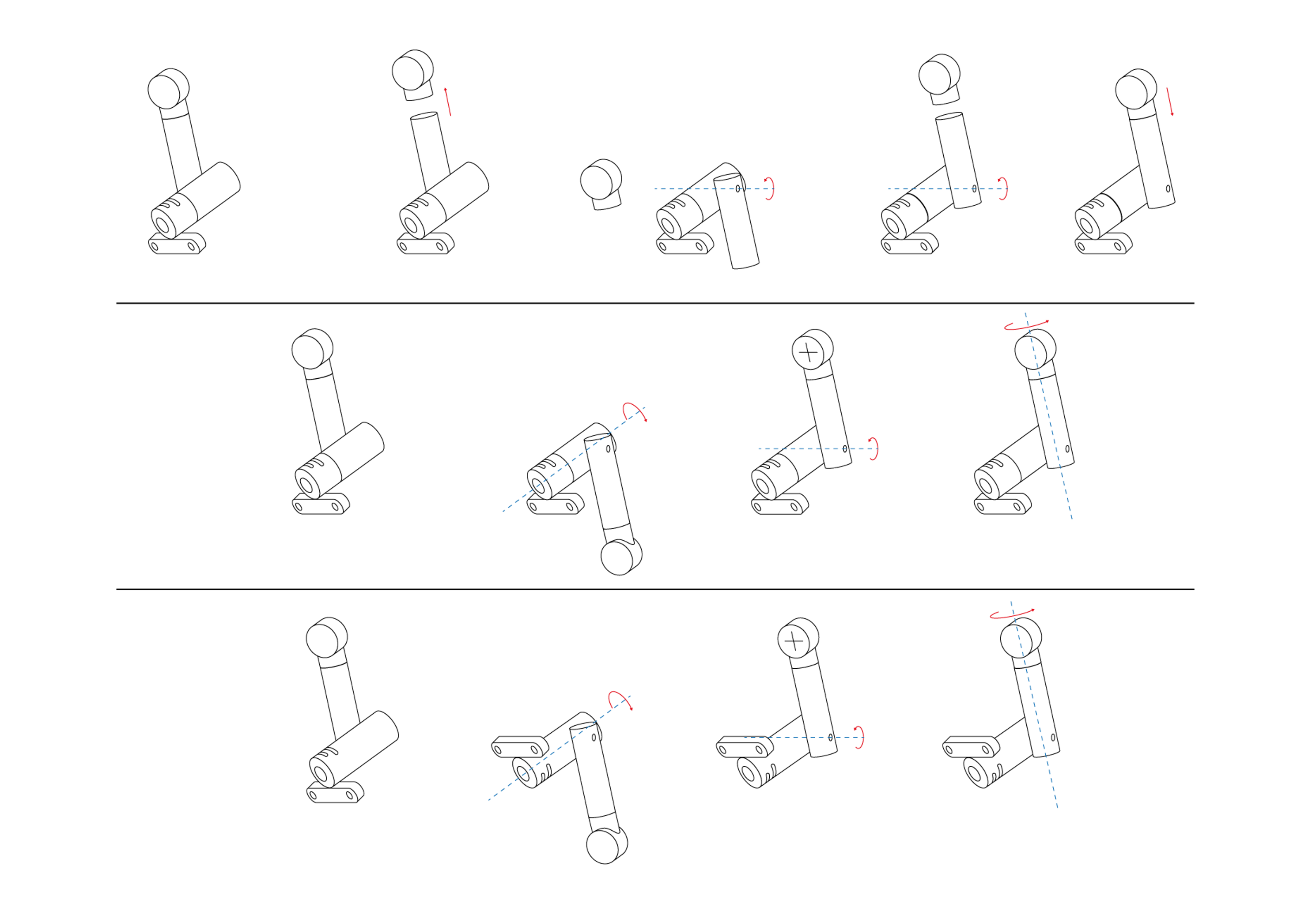

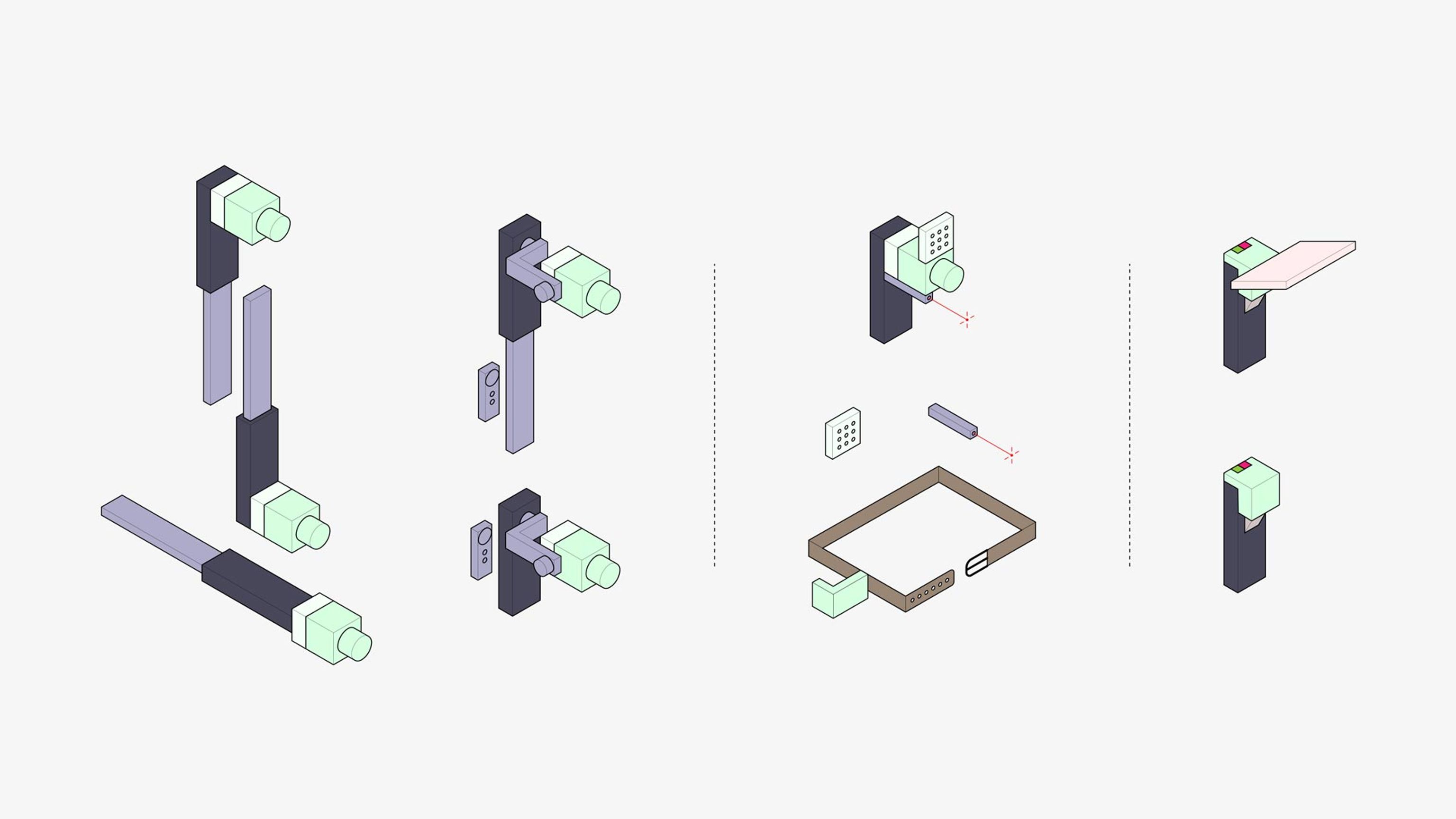

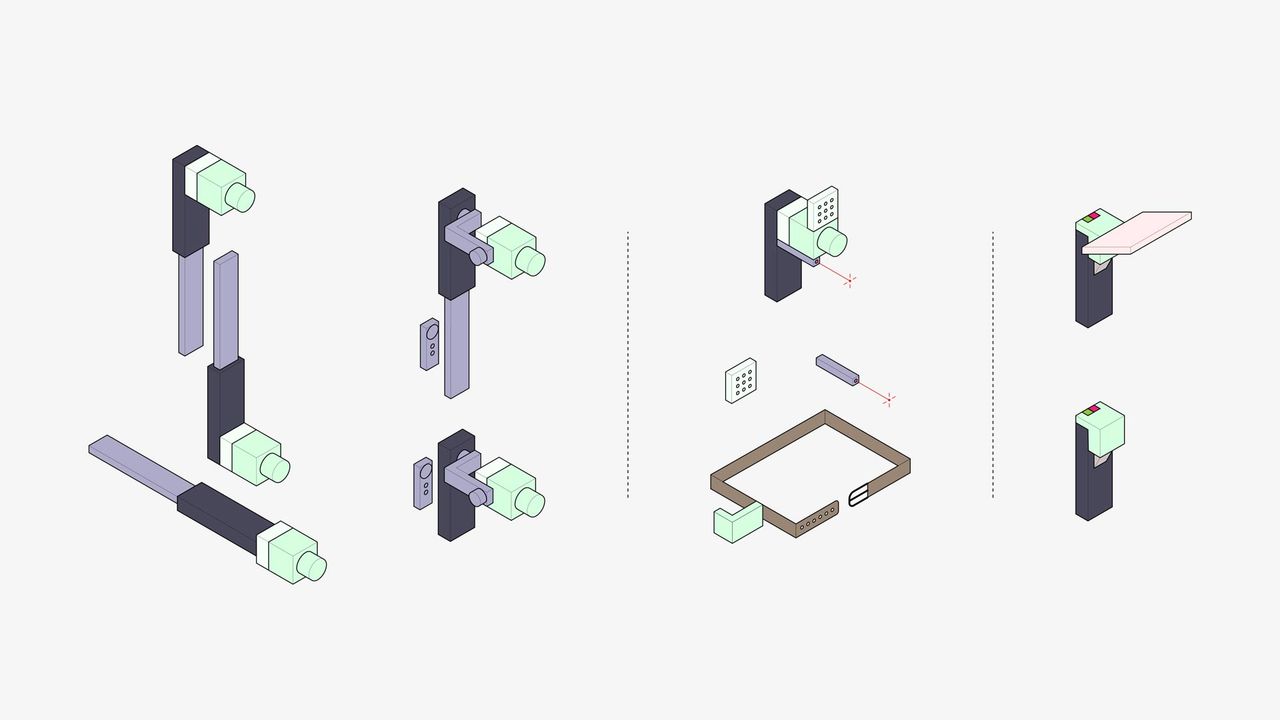

WAND consists of a camera module and a control module.The two parts connect via a magnet and easily detach for the most constrained shots. The control handle can also be inverted to become a pole for overhead shots. To best suit different users, we also designed the product to be ambidextrous.

WAND is a product system. The two elementary modules (camera and control) are accompanied by a family of accessories to adapt to different use cases, similar to action cameras like GoPro. This architecture makes it easy to evolve the product to meet new needs and to customize accessories for each client, or even for each user.

03.Immersion

To fully understand the use cases, we visited four industrial sites in the aerospace sector already equipped with WAND cameras. Along with the production teams, we identified five use cases, and most importantly, we put words (and sketches) to the areas for improvement.User involvement is a key factor in the success of a product innovation project.

04.Makestorming and prototyping

"We can’t see what we’re filming. "

The selected ideas were quickly modeled in cardboard, wood, and foam, followed by prototypes using additive manufacturing. Prototyping quickly allows ideas to be made tangible and tested directly against real-world conditions.

- 7 hours

- 70 ideas

- 40 sketches

- 6 "monster" prototypes

- 1 product line scenario

Prototype and test what matters.

05.Innovation and development

We provided a strategic vision for the product. The main industrial processes selected, additive manufacturing, and machining, do not require tooling. These processes allow industrial versions to evolve. DIOTA can quickly market, compile customer feedback, and schedule frequent product updates. This industrial strategy is adapted to its scale and sales volumes.

Design to cost

Achieving maximum impact with minimal resources.

By modeling manufacturing with 3D printing, we managed to arrange all the components in a compact architecture and with a minimum of parts. This optimization made it possible to halve the cost of the product. WAND integrate:

- an industrial camera

- cutscenes

- adjustment functions

- a bright charge indicator

- a joystick

- a control trigger

- a battery connectors

- etc...

Transmission

ENTREAUTRE shared its network of manufacturing subcontractors to facilitate connections and kickstart the project’s industrialization phase. Our working method and the continuity between design and engineering allowed us to quickly transition from prototypes to a first production run. The first products have arrived at the workshops and are already being used on production lines to check the assembly of helicopter turbines or aircraft wiring.

Results

Positive impact

A range of high-tech products manufactured in France to enhance quality control in the aerospace sector.

Simplicity

Thanks to 3D printing manufacturing, we were able to reduce the number of plastic parts and achieve a minimalist and clever construction.

Satisfaction

The ergonomics, greatly improved compared to the previous generation, provide comfort and precision for factory operators.