Rethink an essential of the Quechua luggage

01.Brief

Quechua asked us to develop an entry-level hiking backpack, available in two sizes (20L / 35L), aimed at occasional hikers. The challenge: meet a shortened development timeline of 4 months instead of the usual 10. While adhering to the brand's design language and maintaining an affordable price, this new design must also reduce its CO2 impact by 20% compared to previous models.

02.User needs analysis

The existing product is aging, but its features are still highly valued by users. To refresh this icon of the range, the new backpack must be both attractive, lightweight, durable, and comfortable.

The retail price is also a key factor in the design and development of this backpack. This choice meets both economic goals and the frugality required to address environmental challenges.

" We need to have the finalized prototypes within 4 months to take them for user testing. "

03 .Design language

The analysis of the existing product is a necessary step when it comes to a redesign. We keep what works and improve what needs to be enhanced.

We are keeping:

- The back structure and its architecture

- The shoulder straps

- The waist belt

- The pocket functions

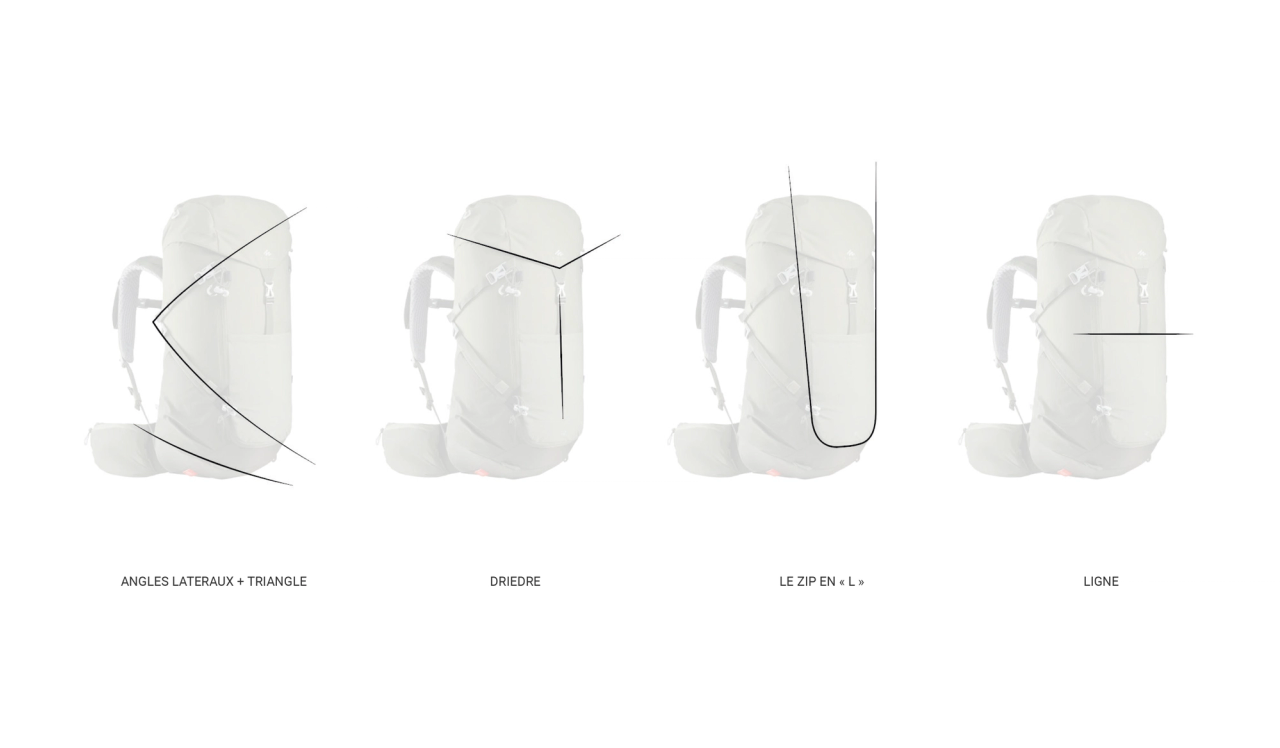

The MH100 backpack is a reference that coexists with more recent products – the MH500 range – which has been commercially successful. To strengthen the consistency of the range, we are drawing inspiration from this model and its key features for our sketches.

04.Creation

Once these functional and formal constants are defined, we move into the execution phase using the designer's tools: rough sketches, scale models, 2D Illustrator designs, and 3D Gravity Sketch models.

05.Development/prototypage

We proposed different concepts – all consistent with the brief. Some designs emphasize sportiness, while others are more technical. The client chose the design that best suited the various target audiences and maintained coherence with the existing ranges.

Once the solution is selected, the work involves a creative back-and-forth with the prototype developers at Quechua's design workshop. Starting from our 2D drawings, we create 3D volume models (known as "3D potatoes") to physically assemble the initial textile shapes. These volumes allow for a precise analysis of what needs to be adjusted: raising a seam, removing material, tightening the fabric, etc. They are also used to verify the structure, optimize the pattern to minimize waste, assess the overall proportions, and begin envisioning the accessories to be used.

After collaborative work sessions in the DECATHLON MONTAGNE STORE workshops, numerous back-and-forth iterations helped mature the solution. This agile approach to the design process enabled the delivery of an advanced prototype quickly, saving several weeks in the development timeline.

When it came to choosing materials and finishes, eco-designed materials were naturally selected to meet the new condition set by the group: every new product released in stores must have a 20% lower CO2 impact than its predecessor.

Another way to limit environmental impact is to avoid product replacement due to breakage. This requires careful attention to each component: construction, assembly, zipper installation, etc. Every element was carefully selected, impacting the product's aesthetics. For instance, the buckle colors will no longer match the bag's colors; they are standardized products made from recycled plastic, predominantly black. This ensures easy, identical replacement in case of damage.

One of the initial requests was to reconsider the bag’s design: with or without a top lid? Indeed, traditional hiking bags typically have a top lid that covers the body (from back to front) to protect the contents. However, for some users, the lid can be cumbersome. In this case, the bag features a lid that closes at the back, combining functionality, aesthetics, and range consistency.

06.Usage tests

Once the prototypes were completed, the bags were sent for field testing and subjected to user feedback. This is a crucial step that provides us with concrete insights. Users are stringent, and their feedback is invaluable to us as designers.

Overall, our proposals were very well received, and each product advantage was fully recognized. However, users made a clear decision: the 35L version will have a front-facing lid.

Result

Positive impact

Through the choices of components made as well as the industrial solutions identified jointly with the design teams, we have managed to reduce the CO2 impact by 20% compared to previous versions (source Decathlon).

Simplicity

We inserted ourselves into the group's design strategies, both in terms of internal methods and current design languages. The design of the products reflects this. They are very simple, without frills and therefore very effective, perfectly aligned with the rest of the products in the range.

Satisfaction

These products have a rating of 4.7 and 4.6 out of 5 in customer reviews on the DECATHLON website. This confirms to us that customer users are fully satisfied with these new designs dedicated to hiking.