Our experiments with 3D ceramic printing

01.Low-tech Cooler

In collaboration with Bon Sens – Low-tech & Design and with valuable advice from Rémi Pérony, we are working on the creation of a low-tech ceramic cooler.

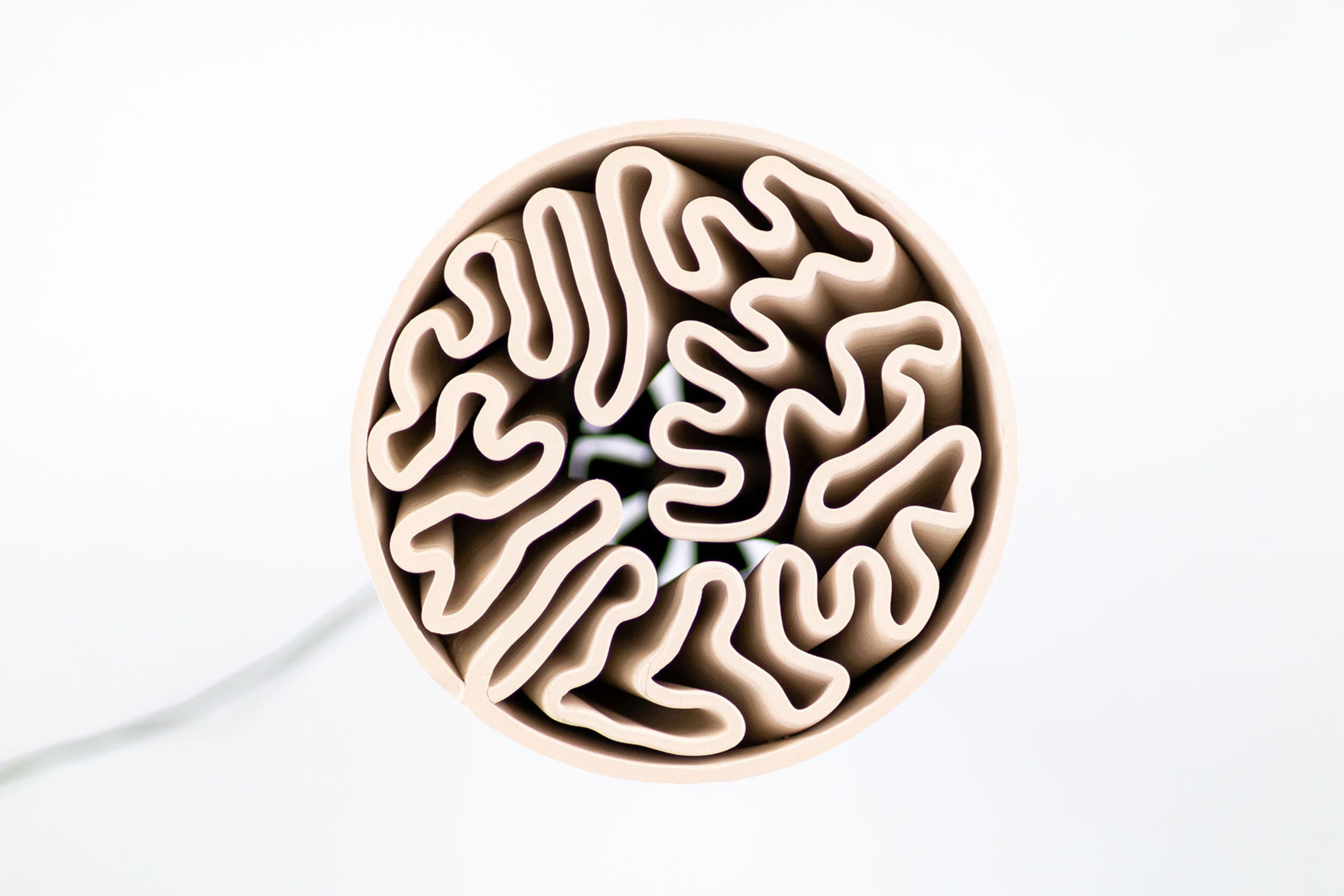

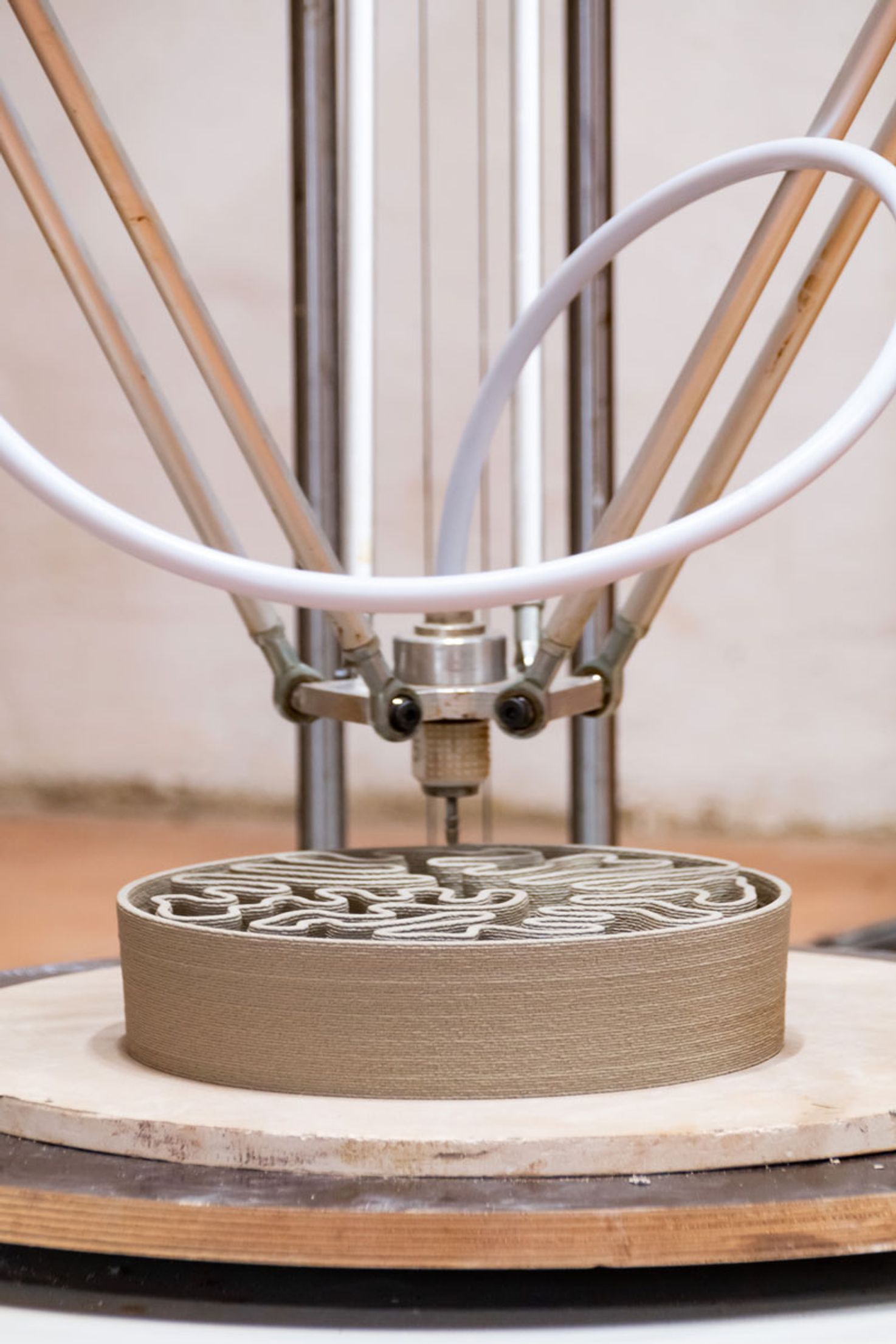

We started with a simple principle inspired by traditional practices: a porous terracotta container filled with water. Using a ventilation system (from recycled electronics), the airflow across the wet surface allows water evaporation, producing cool air.

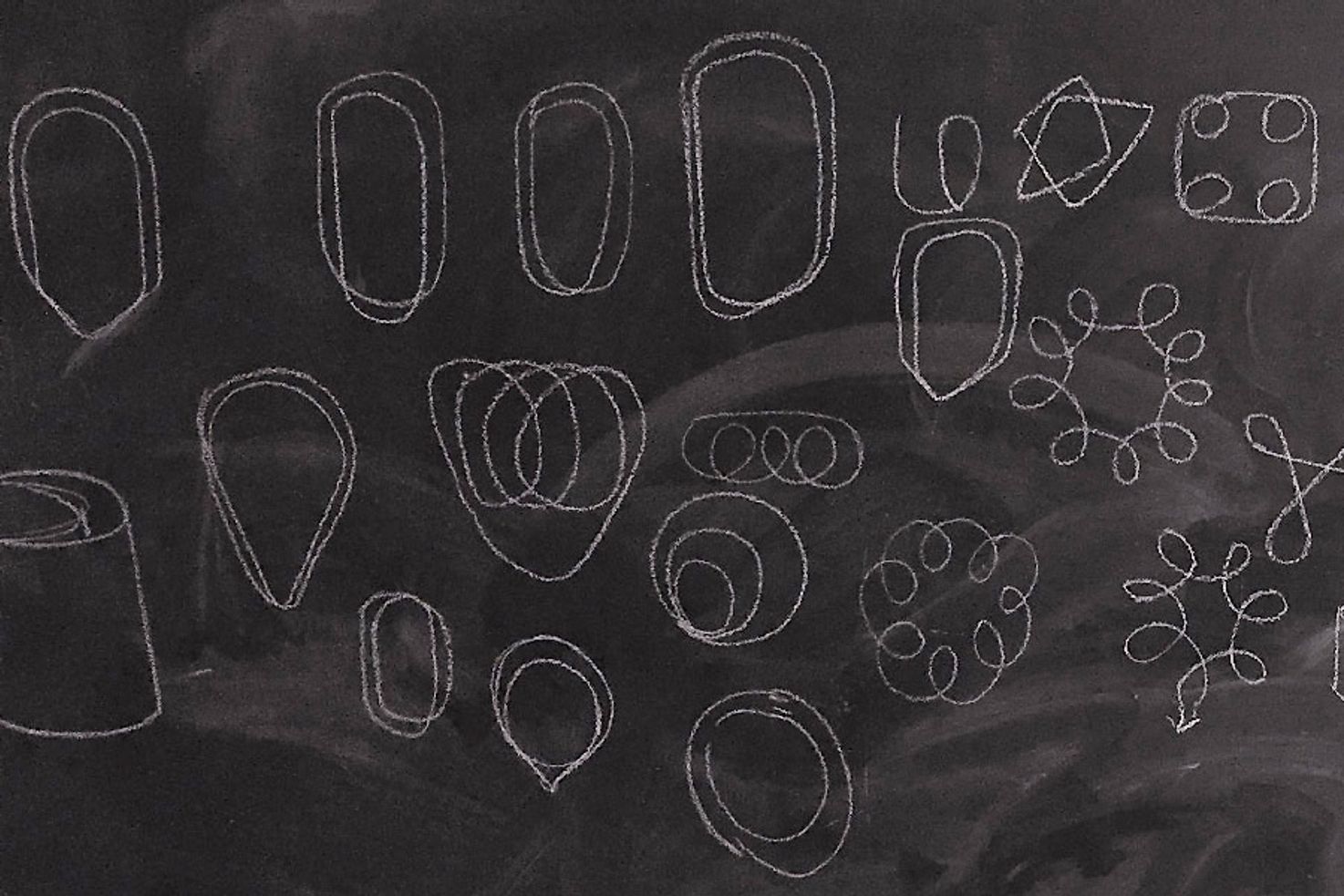

To maximize the cooling effect, we aim to increase the surface area of the wet walls in contact with the ventilated air. The 3D ceramic printing technology at 8 Fablab Drôme allows us to test complex forms inspired by coral structures. This technical constraint becomes the aesthetic signature of the object.

“Create a biomimetic identity”

With the 3D ceramic printer by increasing surface interaction.

02.Collaboration

Advanced technology for an ancient material

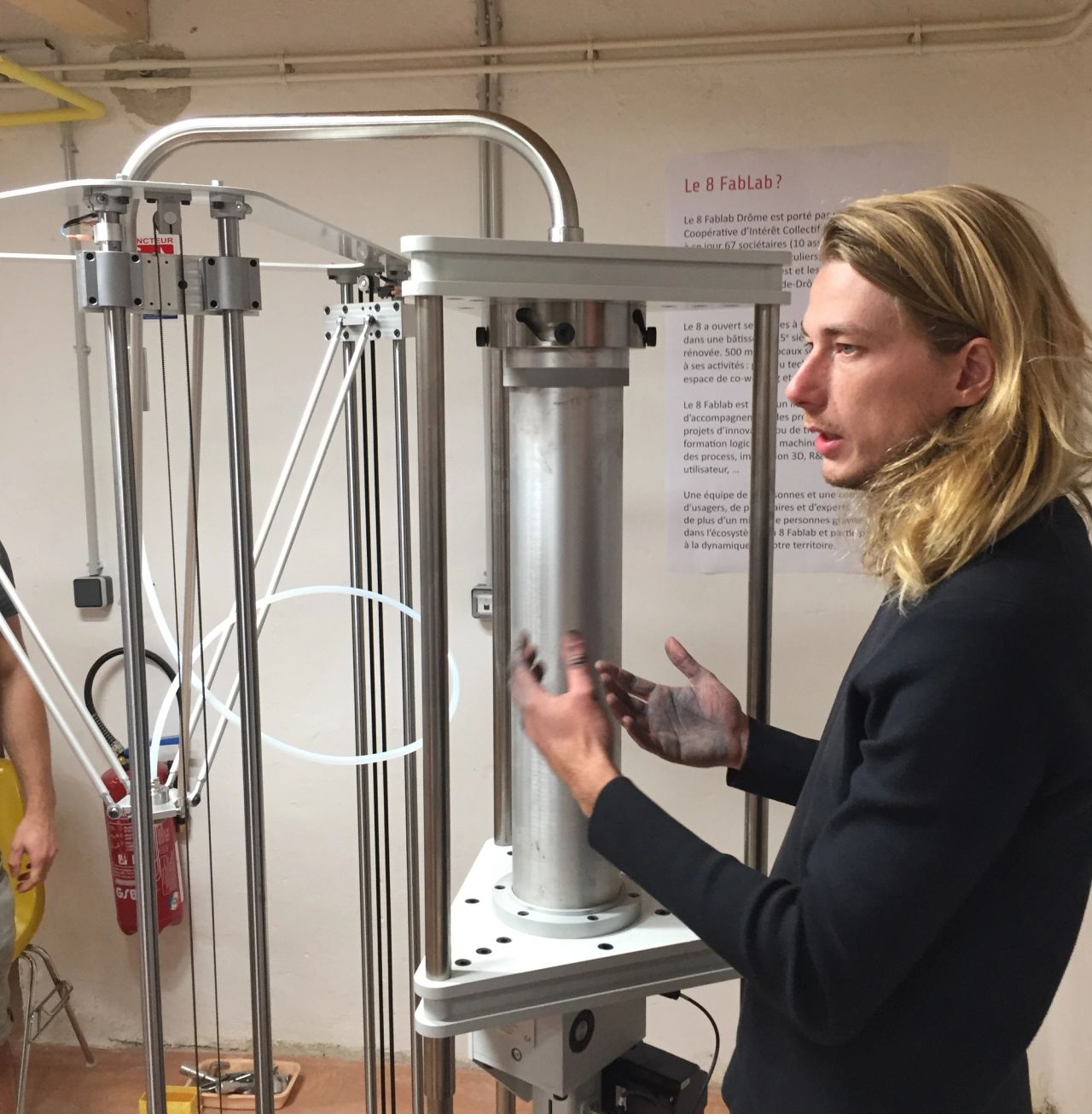

Entreautre is a partner in a collective project centered on 3D ceramic printing. To experiment with the material and the process, we acquired an innovative machine installed near our offices at 8fablab. The 3D ceramic printer is an exclusive machine created by Dutch designer Olivier Van Herpt. Ours is one of the few that exist outside of his workshop.

Project Partners:

- 8fablab – MIT-certified Fablab

- Entreautre – Cross-disciplinary design agency

- Less is More Factory – Cultural creation consultancy

- bf – Innovation support in the arts

- 369 Editions – Multi-disciplinary publishing house

03.Collections

Having access to a unique machine allows us to imagine new objects, not just vases. We reinterpret traditional techniques by exploring the properties of the material, focusing on functionality without sacrificing aesthetics.

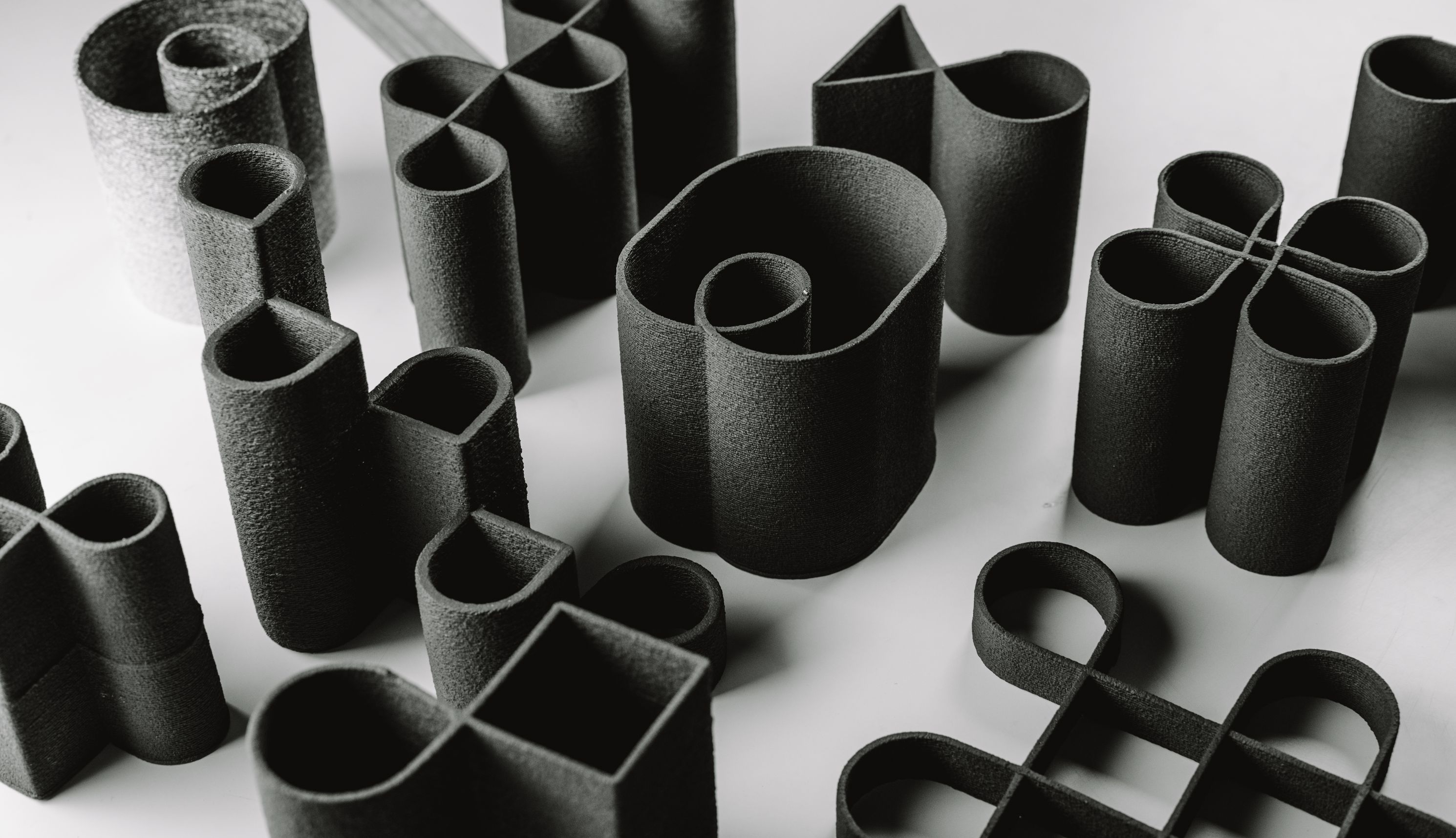

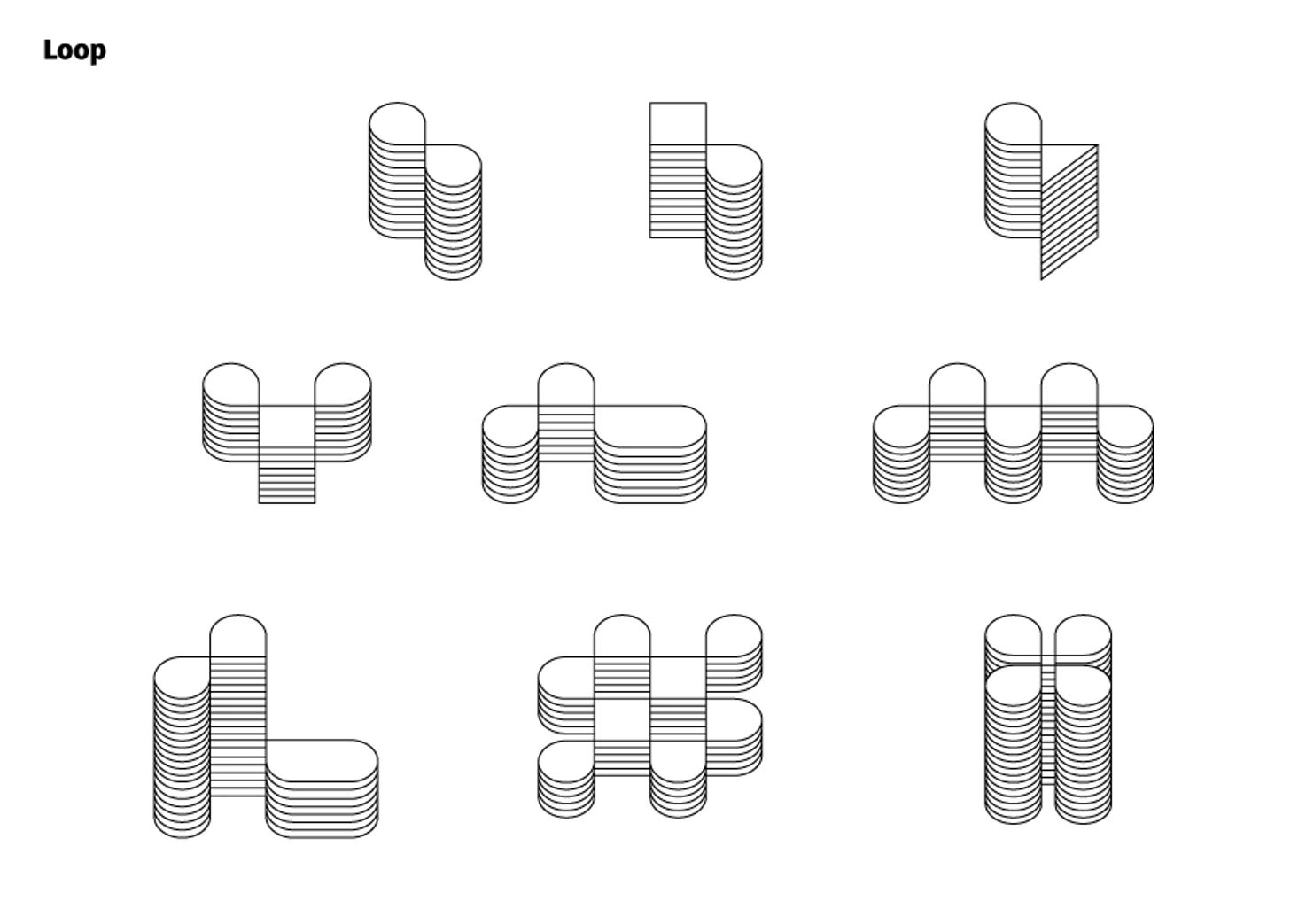

Loop

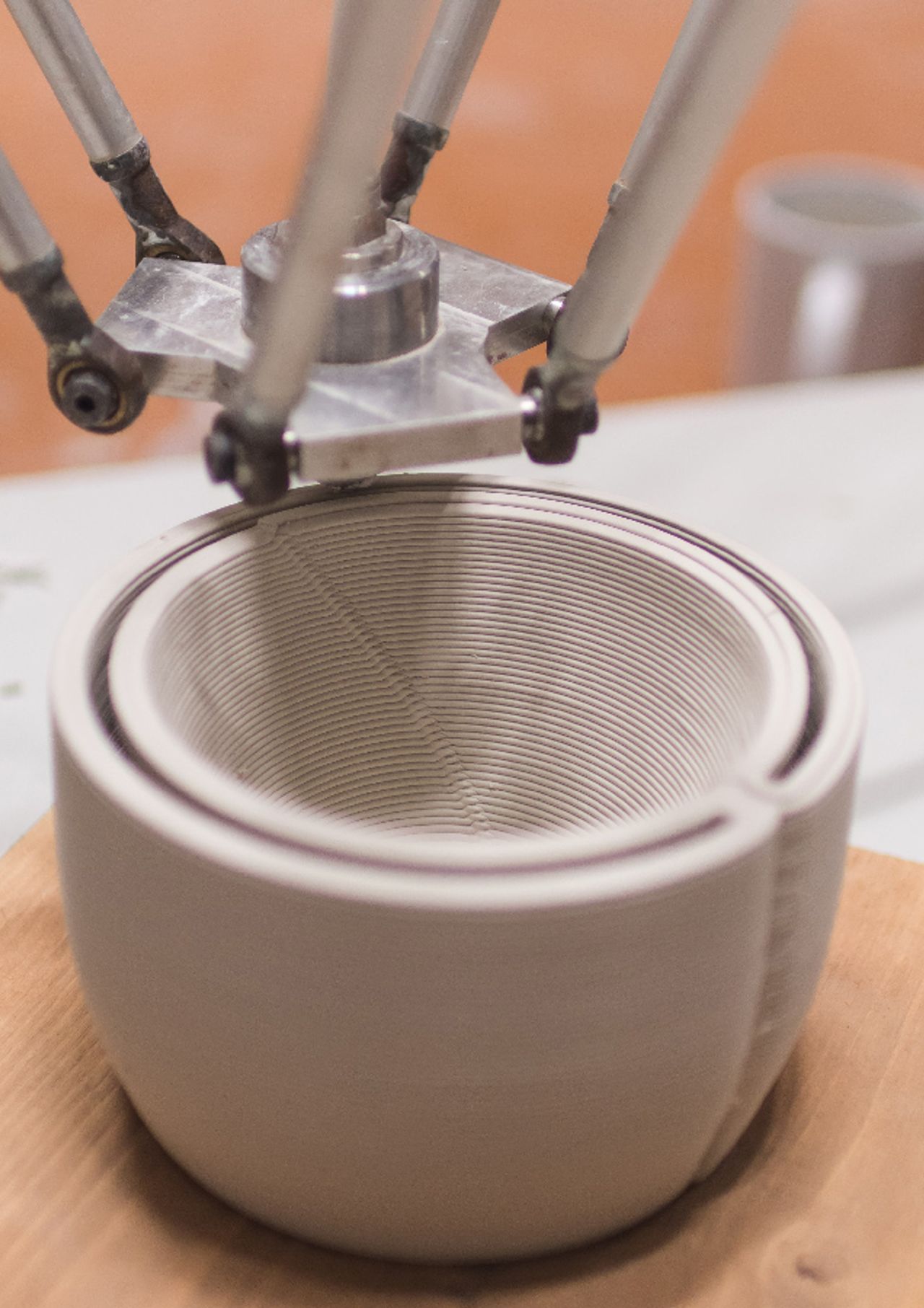

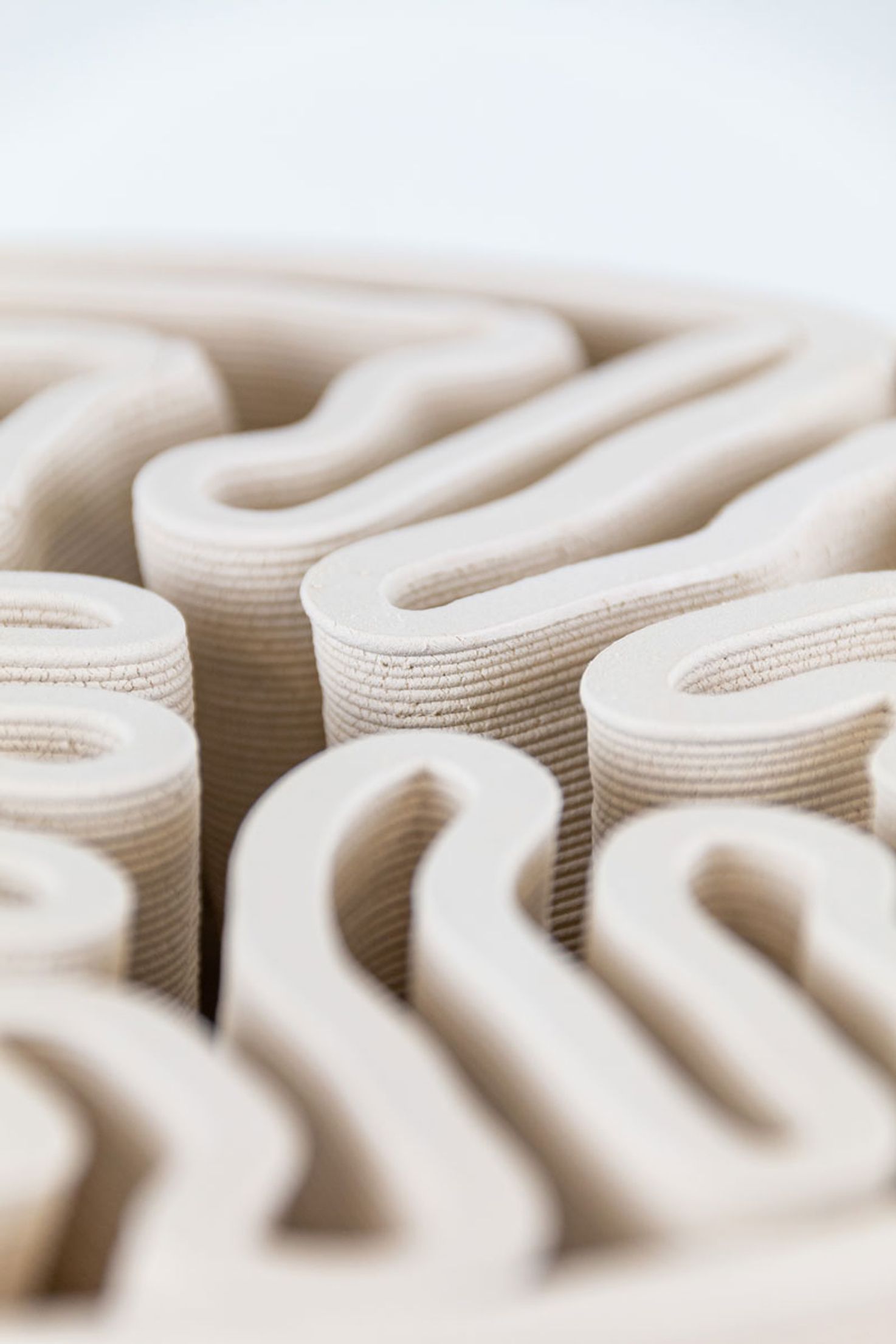

Our first project takes advantage of the ductile nature of ceramic to create loops and build volumes with a continuous coil of material. The interweaving of the walls creates a complex, sturdy structure with the precision and quality of a digital tool. However, the original software for 3D printing only allowed for a continuous coil along the perimeter of the object, without crossings. This was a software limitation, not a material one, as the soft clay could theoretically form loops.

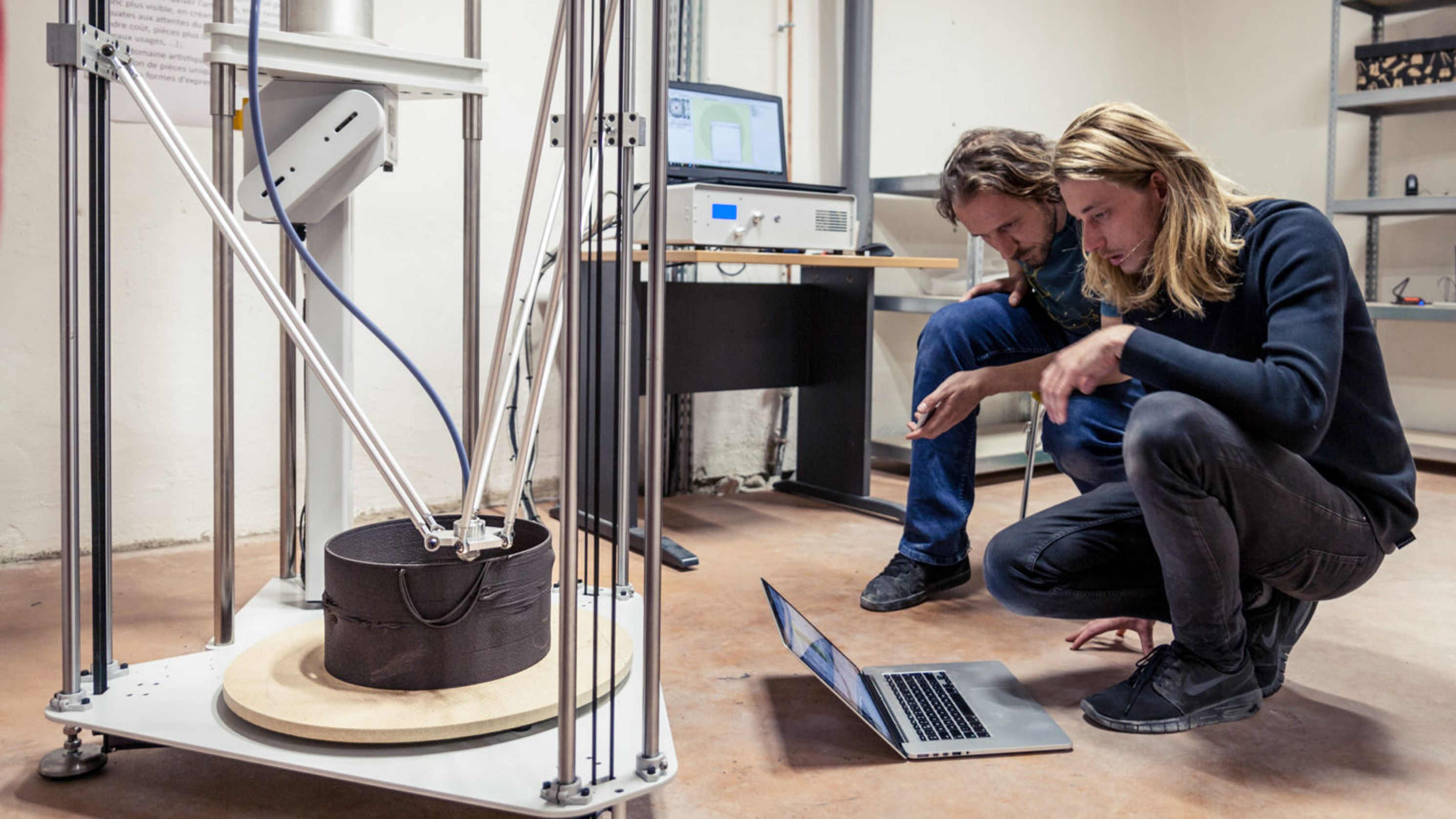

With the help of our partner at 8fablab, who has expert knowledge in 3D printing, we worked directly on the code to bypass the machine’s limitations. This programming work was unusual for designers, but it allowed us to fully take ownership of the process.

The first objects in the LOOP collection use intertwined loops of material to form volumes in successive layers. The additive manufacturing process gives the created vases and pots a unique texture that contrasts with their simple form, highlighting their origin.

The close attention required by the process is productive: witnessing every step of the fabrication allows us to correct flaws and spark new ideas. The 3D ceramic printer is sensitive and requires constant monitoring—it's never left alone!

Large pieces push the process to its limits, with the weight of the clay leading to significant deformation during drying and firing.

Double wall

For our second project, we created a hollow double-wall body in a single piece.

Our goal was to take advantage of the material’s properties to create a self-watering pot. The natural porosity of the ceramic allows plants to hydrate at the right pace.

The research and experimentation conducted in collaboration with project partners allow us to work at the intersection of design, engineering, and craftsmanship, reinterpreting one of the oldest forms of craftsmanship in the world.

We are pushing the machine in a direction different from its creator’s original intention. The unique pieces produced in this research differ significantly from traditional, artistic, or industrial productions. By adopting a design specific to the process and the material (and the quirks of the machine), we create a new formal language.

Results

Positive impact

The possibility of manufacturing unique pieces using a very noble material. Perhaps a process of the future for local production.

Circularity

Everything that comes from the earth, returns to the earth.

Simplicity

A simple cord of material to create incredible objects.

Satisfaction

Very soft objects, full of meaning, that we want to touch and install in our home.